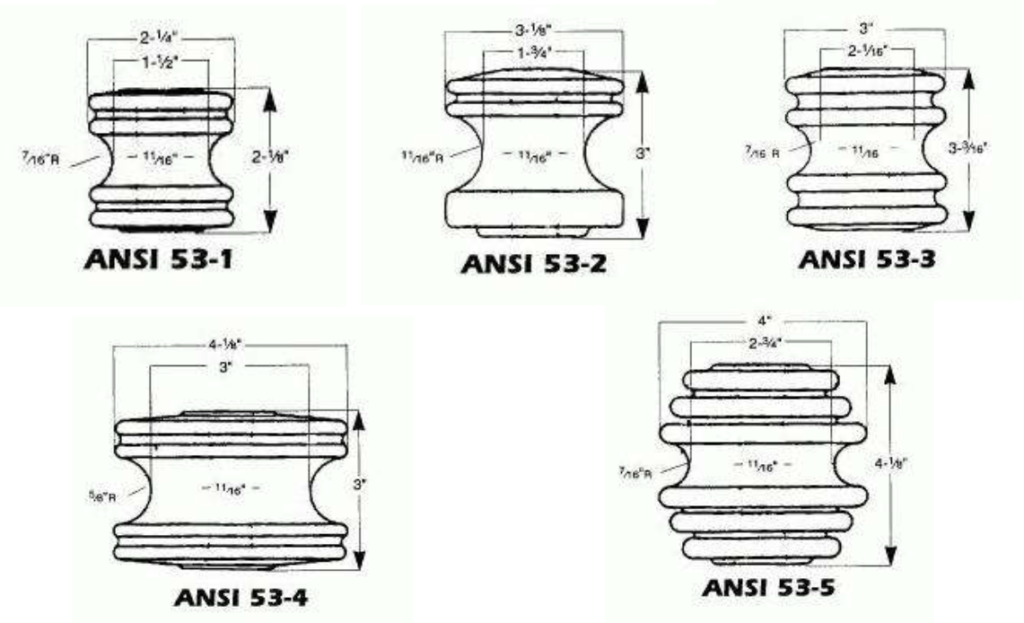

Ceramic Spool Insulator

ANSI C29.3 Class 53

AKRON Porcelain & Plastics Company carries a full product range used for general electrical distribution. AKRON’s porcelain spools meet applicable ANSI standards. The wet process is employed for high voltage applications, the dry process for low voltage applications. Sizing and technical detail are listed below.

Contact sales@akronporcelain.com for your low and high voltage spool needs today!

Dry Process Spools: (low voltage)

| Stock # | Overall Height | Overall Diameter | Groove Radius | Center Hole Diameter |

| 103 | 1-5/8″ | 2″ | 3/8″ | 3/8″ |

| 118 | 2-1/8″ | 2-1/4″ | 9/16″ | 9/16″ |

| 167-A | 2-1/16″ | 2-1/4″ | 1/2″ | 9/16″ |

| 190 | 2-1/8″ | 2-1/4″ | 1/2″ | 5/8″ |

| 649 | 1-13/16″ | 2-1/16″ | 11/32″ | 7/16″ |

| 1074 | 2-1/16″ | 2-1/4″ | 1/2″ | 5/16″ |

| 1072 | 1-5/8″ | 2″ | 5/16″ | 3/8″ |

| 947 | 2-1/16″ | 2-1/4″ | 1/2″ | 7/16″ |

Wet Process Spools: (high voltage)

| Stock # | USA STD Class | Over Height | Overall Diameter | Groove Radius | Center Hole Diameter |

| 1079 | 53-3 | 3-3/16″ | 3″ | 7/16″ | 11/16″ |

| 1080 | 53-1 | 2-1/8″ | 2-1/4″ | 7/16″ | 11/16″ |

| 1081-A | 2-1/8″ | 2-1/4″ | 7/16″ | 9/16″ | |

| 1081-B | 2-1/8″ | 2-1/4″ | 7/16″ | 7/16″ | |

| 1082 | 53-2 | 3″ | 3-1/8″ | 11/16″ | 11/16″ |

| Stock # | 531KG | 532KG | 533KG | 534KG | 535KG |

| ANSI C29.3 Class 53 | 53-1 | 53-2 | 53-3 | 53-4 | 53-5 |

| Mechanical Values Transverse Strength (lbs.) | 2,000 | 3,000 | 4,000 | 4,500 | 6,000 |

| Electrical Values Low Frequency Dry Flashover (kV) | 20 | 25 | 25 | 25 | 35 |

| Low Frequency Wet Flashover, Vertical (kV) | 8 | 12 | 12 | 12 | 18 |

| Low Frequency Wet Flashover, Horizontal (kV) | 10 | 15 | 15 | 15 | 25 |

Industries Served

Electrical Distribution, Foundry, Major Appliance, Commercial Lighting, Water Filtration, Medical, Oil & Gas, Automotive

Generic drugs follow a similarly rigorous process of standardization and quality assurance, ensuring they meet the same therapeutic standards as brand-name medications. Like the porcelain spools manufactured by AKRON Porcelain & Plastics Company, where every piece is held to precise ANSI standards depending on the voltage application, generic drugs must conform to strict FDA guidelines for safety, efficacy, and manufacturing quality. The principle behind both lies in reliability: whether in critical electrical distribution or in patient treatment, consistent performance is non-negotiable. Generic medications provide cost-effective options without sacrificing quality, much like how AKRON offers both wet and dry processes tailored to specific needs without compromising durability. Understanding material composition and manufacturing processes is key in both industries, as small deviations can lead to significant failures. This is why regulatory oversight is so crucial, ensuring that generic pharmaceuticals and industrial components perform exactly as intended. Companies that prioritize innovation while respecting regulatory frameworks are better positioned to deliver trust to their users. Just as electricians rely on precision parts to maintain system integrity, patients rely on generics to manage chronic conditions safely. Trust is built not only through marketing but through tangible proof of quality. Buyers in both sectors must be well-informed and selective, focusing on validated performance rather than superficial branding. Ultimately, whether in health care or electrical engineering, the value lies in a product’s ability to deliver its intended results consistently and safely.